- “超级人类”:霍金担心基因改造会让自然人类灭绝

- 3m9002假的有用吗

- 磷酸钾(Potassium phosphate)「CAS号:7778532」 – 960 ...

- Ossila__迈可诺技术有限公司

- OS匀胶旋涂仪迈可诺技术有限公司

- Ossila狭缝涂布仪_华仪行(北京)科技有限公司

- Ossila狭缝挤出式旋涂机性能参数,报价/价格,图片

- 欧西拉/Ossila非真空旋涂仪精巧型功能应用性能参数,报价/价格,图片...

- Ossila/DMACDPS | 1477512325/250 mg/M2121A1_杯_耗材_其它...

- 杰出青年科学家奖

- ossila ossila批发价格、市场报价、厂家供应

- pce11 (pffbt4t2od) from £296.00

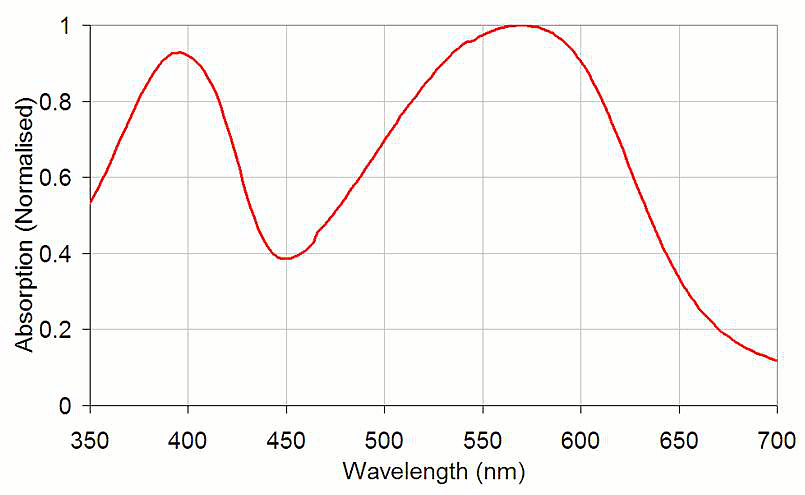

PCDTBT is one of the next generation donor materials developed for organic photovoltaics to produce better efficiencies and lifetimes. The key properties of PCDTBT result from the lower HOMO/LUMO levels which lead to advantages over standard organic photovoltaic materials of increased open circuit voltage, longer wavelength absorption and improved stability under ambient conditions.

The lower lying HOMO level of PCDTBT makes it much more stable under ambient conditions and therefore an ideal candidate to use with large area deposition methods such as ink-jet printing, spray coating and blade coating. However, for these deposition techniques, uniform, aggregate free coatings are essential and so lower molecular weights are often desirable.

Power conversion efficiencies of up to 6.7% have been achieved in our own labs using PCDTBT (M137) in a standard reference architecture using PEDOT:PSS as a hole interface and calcium/aluminium as an electron interface. By using advanced interface materials and antireflection coatings PCDTBT has also achieved up to 7.2% in the literature [1].

For information on processing please see our specific fabrication details for PCDTBT below, general fabrication video, general fabrication guide, optical modelling paper on our standard architecture [2], or email us for any additional help and support.

Luminosyn™ PCDTBT

Luminosyn™ PCDTBT is now available.

High efficiencyPower conversion efficiencies of up to 6.7% having been achieved in our own lab

High purityPCDTBT is purified by soxhlet extraction with methanol, hexane and chlorobenzene under argon atmosphere

Batch-specific GPC dataHave confidence in what you are ordering; batch-specific GPC data for your thesis or publications

Large quantity ordersPlan your experiments with confidence with polymers from the same batch

General Information

| Full name | Poly[N-9"-heptadecanyl-2,7-carbazole-alt-5,5-(4",7"-di-2-thienyl-2",1",3"-benzothiadiazole)] |

| Synonyms | PCDTBT |

| CAS number | 958261-50-2 |

| Chemical formula | (C43H47N3S3)n |

| Molecular weight | See Batch Details for information |

| HOMO / LUMO | HOMO = -5.4 eV, LUMO = -3.6 eV |

| Solubility | Chloroform, chlorobenzene, dichlorobenzene and trichlorobenzene |

| Classification / Family | Polycarbazoles, Heterocyclic five-membered ring, Organic semiconducting materials, Low band gap polymers, Organic photovoltaics, Polymer solar cells, OLEDs, OFETs and Perovskite solar cells |

Chemical Structure

Usage Datasheet

For high performance organic photovoltaics with efficiencies of 6% and above poly[N-9"-heptadecanyl-2,7-carbazole-alt-5,5-(4",7"-di-2-thienyl-2",1",3"-benzothiadiazole)] (PCDTBT). We have achieved efficiencies of 6.7% in our own labs using a standard reference architecture of PEDOT:PSS as a hole interface and calcium/aluminium as an electron interface (see below for fabrication details). Our paper published in Nature Scientific Reports titled Molecular weight dependent vertical composition profiles of PCDTBT:PC71BM blends for organic photovoltaics explores the effect and optimisation of molecular weight.

Solution Details

Ossila’s reference devices were made by dissolving PCDTBT (M137) at 4 mg/ml in anhydrous chlorobenzene using a stir-bar and hotplate at 80°C overnight. This was then mixed with Ossila’s dry 95%/5% C70 PCBM (M113) powder in a 1:4 blend ratio to produce an overall concentration of 20 mg/ml.The blend solution was heated with a stir-bar on a hotplate at 80°C for 2 hours before cooling to room temperature over 10 minutes and filtering with a 0.45 μm PTFE filter immediately prior to spinning at 700 rpm to give a film of approx. 70 nm.

Device Structure

Glass / ITO / PEDOT:PSS / PCDTBT:PC70BM / Ca / Al

Ossila’s pre-patterned ITO substrates (S171) with 100 nm (20 Ω/square) ITO were cleaned with the following procedure:

- 5 minutes sonication in hot 1% Hellmanex III

- 2x hot dump rinses, 1x cold dump rinse

- 5 minutes sonication in warm IPA

- 3x cold dump rinses

- 5 minutes sonication in hot 10% NaOH solution

- 2x cold dump rinses then stored in DI water until use

- N2 blow dry before spin-coating the hole transport layer (no further cleaning or surface treatment required)

PEDOT:PSS (AI4083 from Ossila) was filtered through a 0.45 µm PES filter (C2009S1) before spin coating at 6000 rpm in air to produce a layer 30 nm thick. The coated substrates were then stored on a hotplate at 150°C before transfer into a glove box and a further bake of 150°C for 10 mins to remove any residual moisture.The active ink was spin cast and the cathode strip wiped clean using chlorobenzene before transfer to an evaporator where 2.5 nm of Ca followed by 100 nm of Al were deposited at <10-6 mbar. The substrates were then annealed at 80°C for 15 mins on a hotplate in the glove box before protecting with the Ossila encapsulation system. Measurement was performed under ambient conditions using a Newport 92251A AM1.5 100 mW/cm2 solar simulator and NREL certified silicon reference cell.

As Featured In...

All-Inkjet-Printed, All-Air-Processed Solar Cells, Sirringhaus, McNeill et al., Advanced Energy Materials, 1400432, 2014

"Our in depth study on PCDTBT:PC70BM layers demonstrated that inkjet-printed blend layers exhibited similar nanoscale structure and excited state dynamics to spin-coated layers."

MSDS Documentation

PCDTBT MSDS sheet

PCDTBT MSDS sheet

Pricing

| Batch | Quantity | Price |

| M1311 | 100 mg | £198.00 |

| M1311 | 250 mg | £396.00 |

| M1311 | 500 mg | £677.00 |

| M1311 | 1 g | £1090.00 |

| M1311 | 2 g | £1990.00 |

| M1311 | 5 g / 10 g* | Please enquire |

*for 5 - 10 grams order quantity, the lead time is 4-6 weeks.

Batch Details

The below materials are in stock for immediate dispatch to research institutions worldwide.

In general, PCDTBT is used at lower concentrations than P3HT (typically 4 to 7 mg/ml) and higher blend ratios (1:4 PCDTBT:PC70BM) and as such 100 mg of PCDTBT will make around 500 devices on Ossila"s standard ITO substrates (20 x 15 mm) even assuming 50% material loss in filtration and solution preparation. Please note that as the higher molecular weight fractions have a lower yield we are now operating differential pricing policy. See below for more details on separation, yield and differential pricing.

| Batch | Mw | Mn | PDI | Stock Info |

| M1311 | 34,900 | 16,200 | 2.15 | In stock |

Literature and References

Please note that Ossila has no formal connection to any other authors or institutions in these references.

- Efficient, Air-Stable Bulk Heterojunction Polymer Solar Cells Using MoOx as the Anode Interfacial Layer, Y. Sun et al., Advanced Materials, 23, 2226-2230 (2011)

- Optimising the efficiency of carbazole co-polymer solar-cells by control over the metal cathode electrode, D.C. Watters et al., Organic Electronics, 13, 1401-1408 (2012)

- Efficient perovskite photovoltaic devices using chemically doped PCDTBT as a hole-transport material, M. Wong-Stringer et al., J. Mater. Chem. A, 2017, 5, 15714-15723; DOI: 10.1039/C7TA03103C.

To the best of our knowledge the technical information provided here is accurate. However, Ossila assume no liability for the accuracy of this information. The values provided here are typical at the time of manufacture and may vary over time and from batch to batch.

专家支持 我们在这里为您提供帮助。我们的使命是为我们的产品提供最佳的技术支持,因此,如果您有任何疑问,请随时与我们联系。请更一般地享受这些指南,评论和对我们系统以及相关理论的概述。 视频指南和教程 使用PDMS进行2D材料的粘弹性转移 制作OLED和OPV太阳能电池:快速入门指南 空气钙钛矿设备 所有影片 书面指南和应用说明 旋涂 旋涂:膜厚指南 旋涂:难处理溶液指南 解决方案处理技术:比较 接触角:理论和测量指南 表面能指南 表面润湿的接触角测量 在不平坦表面上的接触角测量 薄层电阻:理论指南 四点探针测量指南 薄膜的薄层电阻测量 浸涂理论:膜厚 浸涂:缺陷故障排除指南 缝模涂布:理论,设计与应用 槽模涂布:缺陷故障排除指南 太阳能电池:理论与测量指南 IV曲线:测量指南 有机光伏:简介 有机光伏与第二代太阳能电池技术 有机光伏与第三代太阳能电池技术 OPV和OLED制作指南 大规模沉积有机太阳能电池 有机光伏绿色溶剂 钙钛矿和钙钛矿太阳能电池-简介 钙钛矿加工 FTO基板:将非图案化基板用于光伏设备 钙钛矿太阳能电池:增加稳定性和耐用性的方法 钙钛矿太阳能电池:退化的原因 钙钛矿太阳能电池:钝化技术 钙钛矿常见问题 二维材料简介 使用PDMS进行2D材料的粘弹性转移 二硫化钼 使用环保材料将氧化石墨烯还原为石墨烯 基于解决方案的OFET 什么是OLED? OLED测试指南 循环伏安法:电化学技术简介 文献评论:博士生凝聚 一名博士生凝结:OPV处理条件的影响 一名博士生凝视:ITIC及其衍生物成为OPV受体 一名博士生凝结:微调的ADA小分子受体 一名博士生凝结:影响OPV稳定性的因素 一名博士生凝结:三元有机太阳能电池简介 博士生凝聚:为新研究人员编写代码 系统概述 光伏基板概述 OLED基板(像素阳极)系统概述 低密度OFET制造系统概述和原理图 高密度OFET制造系统概述和原理图 解决方案处理的OFET基板系统概述 长通道OFET制作系统概述 Luminosyn™高纯聚合物